Testing & Prototyping

Prototyping is an integral part of the system design process. Early visibility of the prototype can identify problems and minimize risk, while increasing output, reducing development costs, and accelerating development cycles. Prototype production is a vital process, which enables new products to be manufactured and considers the whole lifecycle from conception to end-of-life. SpecForge provides solutions that give customers a competitive advantage.

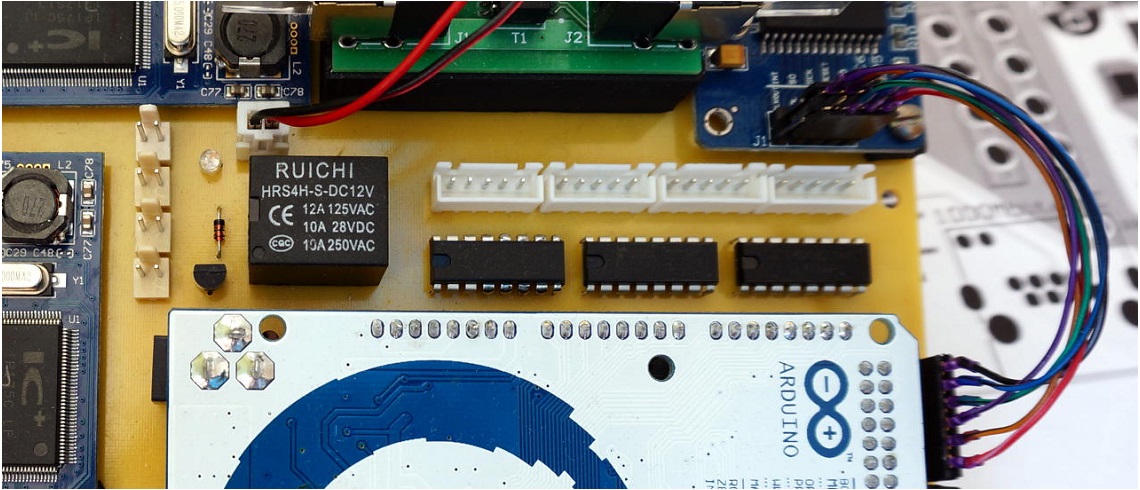

During the development of your product, our PCB designers work closely with electrical engineers to ensure that the location of components and their designators correspond to the requirements of the circuit and structural parts of the project. We also cooperate with manufacturers that provide the efficient assembly support and reduce marriage output during production.

The main stages of prototype development

- Conception and Circuit design - from discussion the idea of general structural scheme of device to the concept, development methods of testing devices. At the same stage, the choice of platform, which is determined by factors such as consumption, capacity, data signaling rate, as well as software development tools.

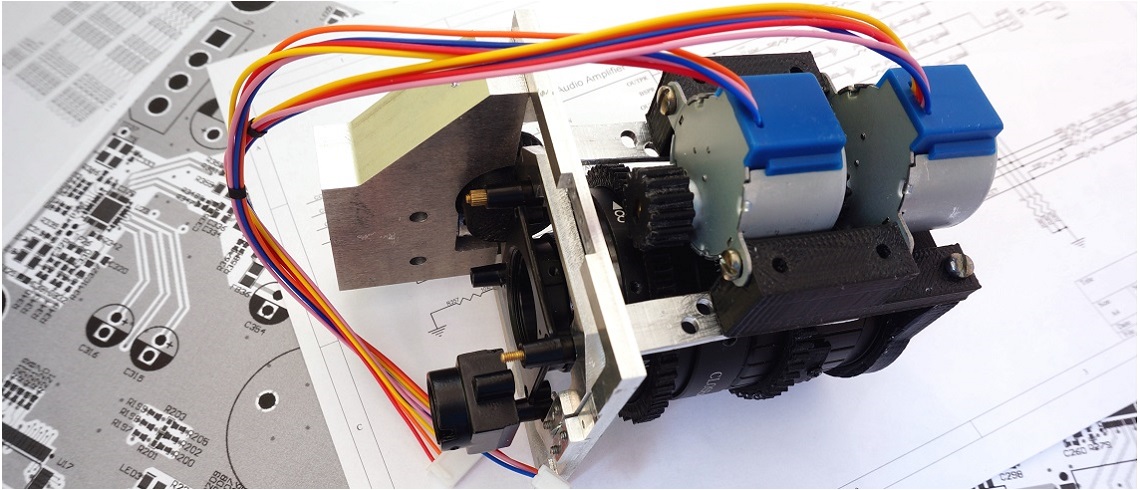

- Constructing - case design, mechanic parts (can be motorized or not), rigging, ergonomics device

- PCB design

- Order and production

- Software development, elaboration of test plan

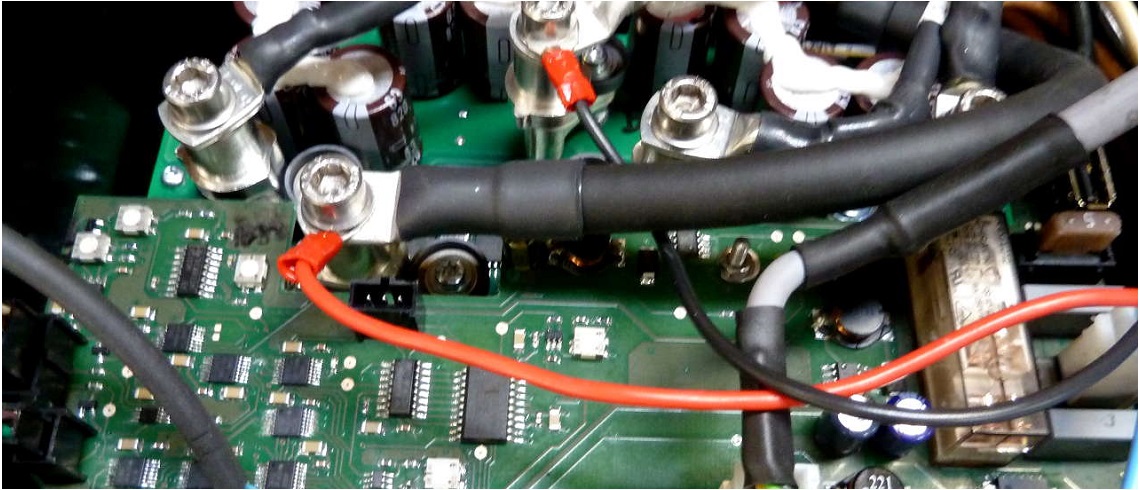

- Assembling, setting and general testing

- Testing of experimental batch (in the case of mass production)

We can attract professional third companies by polymer coating, metal processing, milling and turning, casting in the form of metal parts, casting plastic housings, application of voltaic coating.

Complex testing applied throughout new product development, saves customers money while reducing manufacturing downtime. Prototypes can be tested for aspects like design defects and ease of use, two things that are decisive if your product is going to be a success. You need to make sure that everything works the way it should - and that your customers can understand how to make it work, too.